Pack Manufacturing Flat Filling Equipment

Whether filling liner or seed trays or large pots, the Pack Manufacturing Flat Filling equipment line provides the absolute gold standard in efficiency and speed. Each piece of Pack Manufacturing Flat Filling Equipment is optimized to remove the bottlenecks in productivity and create new efficiencies in production. All Pack Mfg. Equipment is designed to operate with the absolute minimum maintenance. Pack Manufacturing Flat Filling Equipment will allow you to maximize your production with a minimum amount of labor.

As with any successful business, growing is often associated with growing pains, like costs for upgrades and extra labor. The Pack Manufacturing equipment line allows you to invest your money where you will see the fastest return.

Every process you can efficiently automate allows you to save money by performing that process better, faster, and with less labor involved.

Pack Manufacturing Flat Filling Equipment is dependable, rugged, and operates with minimum maintenance. Our filling equipment is versatile enough to meet any filling need, and we can customize your equipment to fit whatever needs your operation has.

If you don’t see what you are looking for, ask!

We can do it!

The decision to upgrade is often a hard one, but just consider how quickly the savings on labor and materials will add up, not to mention the permanent increase in production capabilities. Being able to produce vastly more plants a day means your operation can make more money in the same amount of time. Reducing the amount of labor involved means that those same plants now cost less to produce. We have diligently worked to ensure each piece of Pack Manufacturing Flat Filling Equipment will help your business see the fastest possible ROI.

Flat & Tray Fillers

Flat & Tray Fillers

PM10C

The Pack Manufacturing PM10C Filling System is designed to provide growers with a compact and versatile solution to filling multiple types of containers, including nursery pots, hanging baskets, and plant/ plug trays. The Pack Mfg PM10C includes a variable speed soil filling conveyor, fully adjustable compacting sweepers and a rotating rotary brush to remove excess media from the containers. Excess soil is returned to the lower hopper in the soil return chute system. The PM10C is ideal for operations with limited space of beginning operations on a tight budget. The Pack Manufacturing PM10C has a 12″ wide belt and allows use of the brush to a maximum of 6″ tall. Perfect for filling trays and small pots.

PM1100 Filler

The Pack Manufacturing Company PM1100 is a highly customizable machine, capable of adapting to multiple roles. The PM1100 Filling System is designed to provide growers with a versatile, compact, high speed and uniform solution to filling multiple types of containers, including nursery pots, hanging baskets, plant and plug trays. This equipment includes variable speed controlled soil hopper and filling conveyor. The Pack Manufacturing PM1100 also features a fully adjustable soil agitator, compact roller and rotary brush. Excess soil is collected as the containers are passed across a powered transfer, and all excess is returned to the hopper via the horizontal and vertical auger system to virtually eliminate wasted grow media.

See our PDF for more info. See our video on YouTube.

PM20 Mixer and Flat Filler

The newest member of the Pack Manufacturing Flat Filling Equipment line is here! The Pack Mfg PM20 Mixer and Flat Filler is the economical solution for any small or new grow operation. Without automated equipment, a nursery is forced to depend upon expensive labor. Deciding which equipment to purchase and which to do without is a challenge. Pack Manufacturing just made the decision a lot easier with the combination PM20 Mixer and Filling Machine. Growing media or potting soil is mixed in the integrated 1 cubic yard hopper under the safety-switch equipped, clear polycarbonate hood. The mixed media feeds directly from the hopper to the pot or tray filling line via the auger soil return system. Any excess potting media is safely recycled right back into the hopper for reuse with no waste. To ensure each container is uniformly filled, the Pack Mfg. PM20 is equipped with an adjustable rotary brush and pot sweeper, along with an extended 15-inch wide filling conveyor, roller take-offs, and variable speed controls. All this capability packed into one compact, mobile machine makes the Pack Mfg. PM20 Mixer and Flat Filler the easy investment choice for growers on a budget.

PIONEER Filler™

The Pack Manufacturing Pioneer Filler™ is the Newest Economy Flat and Pot Filling system for all your container growing needs. The Pack Manufacturing Pioneer Filler™ is designed with the beginning small business in mind. As you are pioneering your new horticultural venture, the Pioneer Filler™ is there to make sure your new business has all the tools it needs for success. This machine is designed to AFFORDABLY produce up to 1500 flats per hour and 950 seven-gallon pots per hour. The Pioneer™ Filler is 100% Plug and Play, so as you build capital, expand your operations, and invest in new equipment, your new equipment will automatically work with your existing Pioneer Filler™. The Pioneer Filler™ also works from a 240 VAC plug, and comes standard with a one cubic yard hopper, adjustable wiper, powered rotary brush, and powered soil sweep. If you are ready to go to work filling your containers and flats in the most efficient way, look no further for an affordable solution to your labor issue! The Pioneer Filler™ comes equipped with all the standard features included, and any premium or custom feature can be added. All this with the lowest price tag in the industry! Call to reserve yours today!

See our PDF for more info. See our video on YouTube.

TRAILBLAZER Filler™

The Trailblazer Filler™ comes equipped with all the tools your business needs to compete in both quality and quantity with any grower. Growers that have staked their claim and are ready to move to the next level will find the Trailblazer Filler™ as the perfect tool. The Trailblazer is equipped with all of the features of the Pioneer Filler™ and also includes an enhanced auger soil return, powered roller take-offs, a caster mobility kit, and a vibrator motor on the belt to help settle media and eliminate air pockets from tray cells. The Trailblazer Filler™ touchscreen controls allow for fast and intuitive operation. Direct drive gearboxes and all sealed bearings ensure that this machine operates with minimal maintenance. The Trailblazer Filler™ provides growers with a premium solution at an economical price, complete with all the features for amazing performance and extreme dependability.

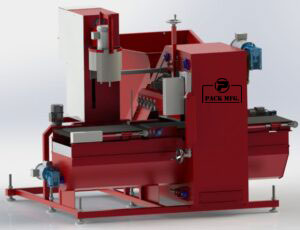

PROSPECTOR Filler™

Strike gold with The Pack Manufacturing Prospector Filler™! This one machine is made to fill all your potting needs. The Pack Manufacturing Prospector Filler™ includes all the features of the Trailblazer and Pioneer Fillers, but includes an Integrated Potting Drill on a separate integrated conveyor. This one machine will allow you to fill flats, trays, pots, baskets, and upgrade plants to higher sizes with just the press of a button. Potting has never been easier than with the Prospector Filler™. Included with all the performance features of the Prospector Filler™ are an extended auger soil return system with a powered roller take off, vibrator motor on the potting belt, powered pot brush, variable speed control on the belt and soil, adjustable potting chute, and a touchscreen control that includes a pot counting system on on-screen setup instructions. The Pack Manufacturing Prospector Filler™ makes setup between potting production a breeze. Drill and potting settings can be saved to the touchscreen and changed with the press of a button. . All the capability and versatility of a production line in a single economical machine make the Pack Manufacturing Prospector Filler™ is one of the best investments you will ever make in your business!

Location

Pack Manufacturing

1219 Belmont Dr.

McMinnville, TN 37110

Hours

We are open Monday to Thursday 7:00 am to 4:30 pm. Friday 7:00 am to 12:30 pm CST.